Gar's Tips & Tools - Issue #176

Weekly-ish access to tools, techniques, and shop tales from the worlds of DIY

Tips and Must-Haves for Small Shops

In this “Ask Adam” video, Adam Savage gets asked what are the essential things to consider when setting up a small home workshop. He points out something that a lot of people likely overlook: the quality, design, and utility of your workbench(es). He says that you should have workbenches that you love being at. I have work surfaces I love and one I don’t. I have two large Biomorph adjustable worktables in my upstairs office/shop/studio and a cheap Harbor Fright workbench in the garage shop. Love the former, hate working at the latter. One of these years, I’ll upgrade my garage shop and I’m sure I’ll spend more time in there as a result. He also emphasizes lights. The more light, the better. I have frequently said the same here and recommended this system which I have bought 3 sets of now. He also loves long power strips and recommends these 12-outlet strips. He points out something you may not have thought of. If you’re a one-person shop, you don’t have to worry too much about overloading a large power strip. You’re not likely to be using more than one (or two) tools at a time. In answer to another question about rust, he recommends one of my fave shop products which I’ve talked about in this newsletter many times: Evapo-Rust.

Elevating Your Workshop Game

This recommended shop tool would likely fit in my “homely tools” category, an indispensable, everyday tool that fades into the background of your work process: apple boxes. Wesley Treat shows you how to build simple, nesting apple boxes which he argues are the kind of tools you don’t realize how bad you need them until you have them in the shop.

Turning Dowels with a Hand Drill and Jig

I’m not a woodworker. I see a lot of these easy dowel-turning jigs using a drill and a blade (here from a hand plane) and always wonder if they’re practical. Or BS. This is one of the easiest and seemingly solid ones that I’ve seen. What do my woodworking readers make of this? Here’s another one using a modified nut.

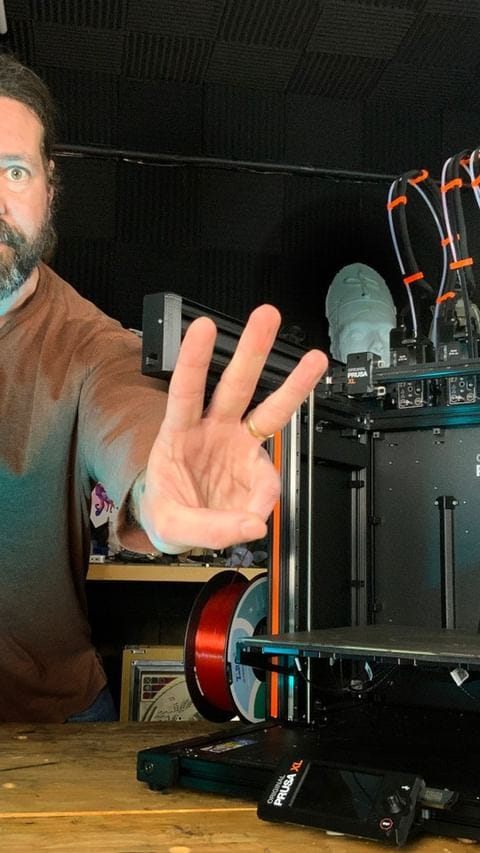

Three Toolchangers to Watch

Caleb Kraft of Make: has started posting short tips and recommendation videos on his Instagram feed. In this installment, he offers three DIY toolchanger projects for 3D printers that he thinks you should keep an eye on: @zombiehedgehog, Vinny5915, and 3DUnplugged. I love efforts like this of people in the know in a given domain telling the rest of us what to pay attention to.

Steven Roberts’ “The Digitizing Report”

It is impossible to overstate what an influence Steven Roberts, aka the High-Tech Nomad, has been on my life as a maker. He was a maker OG who landed on my radar in the mid-80s with his absurdly ahead-of-its-time Winnebiko project, and then the even more amazing BEHEMOTH in the early 90s (see above). I covered these ingenious technomadic projects for Wired, Mondo 2000, The Futurist, bOING bOING, and Make:, subscribed to Steve’s newsletters, and we eventually became friends. We remain so to this day. Steve is one of the most talented and inspiring independent engineers and technical thinkers I’ve ever had the pleasure of knowing. As an engineer with the soul of a poet, he’s the embodiment of his own well-known quote, “Art without engineering is dreaming. Engineering without art is calculating.” So, I was thrilled to hear from Steve that he’s launched a new newsletter, The Digitizing Report. Steve’s latest tech obsession (and business) is digital archiving. He has a huge 48-foot mobile lab that he’s outfitted with a “toolset for recovering analog treasures.” The newsletter covers his media digitizing efforts with the level of useful detail that Steve is known for. Lots of great how-to info here “whether someone is running a business or just wants to put Dad’s musty VHS tapes onto a thumb drive for the kids.”

Buying Longer Than You Need

If you’re not following Kevin Kelly’s Instagram feed or purchased his book, Excellent Advice for Living, here’s another useful, aphoristic reminder. In addition to such life advice, he’s also started a Pattern Language-like series of “LOOK Design Tips." Here are a few:

LOOK Design Tip 51: Arrange a patchwork of uneven parts into a unbroken whole.

LOOK Design Tip 52: Take a conventional simple form and make it very ornate

Shop Talk

Readers offer their feedback, tips, tales, and tool recommendations.

In response to my “Don’t Buy This!” entry in the last newsletter, Lawrence Kampf wrote:

The Ikea MOPPE chests do fine if you give the drawers a sanding on the edges. It doesn’t fix the weird shape of them that I find too deep for their width, but it easily fixes the binding.

Any ideas where to find shallow draw units for storing punches, small chisels, etc? The closest I’ve found so far is oil pastel storage units from art stores.

‘Luck and thanks for the tips!

I knew about sanding (and soaping/waxing the bottom edges, as other readers suggested), but have just been too lazy to try these. I have now tried both. The sanding really does help the drawers slide. The soaping wasn’t as successful for me. I would definitely recommend sanding the bottom edges smooth if you buy these chests.

In answer to Lawrence’s question about shallow drawer units: Have you seen/tried the DeWalt TSTAK IV stackable drawer units? They might meet your needs:

A number of readers were alarmed by the safety implications of recommending angle grinder tool hacks. This response from yrtagentman speaks for others:

Angle grinder "hacks" look useful but are very dangerous. Angle grinders spin at about 10,000 rpm so things - like flying parts or work pieces - can go bad very fast.

Yes. In all posts in this newsletter, in YouTube videos, and the like, you should always make sure that you know the tool, what the tool can do, how the tool wants to hurt you, and safe and secure shop practices. Anything that spins at 5-10,000 RPMs is dangerous. Your safety and the safety of those around you should always be the top priority when using tools, especially aggressive ones like angle grinders. The appeal of "hacks" can sometimes overshadow the inherent risks involved, leading to complacency about safety. It's critical to remember that even experienced pros take rigorous precautions when using such tools.

I was looking at some small craftsman brand drawers the other day and instantly recognized the dewalt drawers. They're identical (save for the colors).

https://www.amazon.com/Craftsman-CMST17804-SYSTEM-SHALLOW-DRAWERS/dp/B09BDLM7JB/

As someone who has made and used Apple boxes. His approach seems spot on. Cheers.