Gareth's Tips, Tools, and Shop Tales - Issue #137

Tips Busters: Amazingly Stupid Tape Tricks

Months back, I proposed the idea of doing a "Tips Busters" section where I deputize readers to try out a tip, any tip they see that appears too good to be true, to determine whether it works, doesn't work, sorta works. I'm still hoping to put such a series together. If you want to bust a tip or have a tip to bust, message me. In the meantime, I'm going to start running pieces from others who are testing and evaluating tips. On this episode of Stumpy Nubs, James looks at a number of dubious (at best) painter's tape "hacks" as found on YouTube. There are many such tips. As James points out, lots of them are just plain silly.

Understanding Tolerances for 3D Design and Printing

Via Maker Update comes this gem of a video on Practical Alchemy about understanding parts tolerances when designing in Fusion 360 (and other CAD programs) and how to ensure that your 3D designed parts will properly fit when sent to a 3D printer. They also show you how to create a 3D printed "Fit Guide" to better understand and accommodate tolerances for your particular printer.

A User's Guide to H-Bridge Motor Drivers

Anyone with even a casual familiarity with hobby electronics is likely familiar with H-bridge motor drivers. So named for the H-like configuration of the circuit schematic, with its 4 switching elements, these drivers allow you to control DC motors for speed and moving forwards, backwards, left, and right. In this DroneBot Workshop, they look at a number of popular H-bridge drivers (e.g. L298N, DRV8871, and the MX1508) and the types of DC motors they can control. At over 1-hour, this is a useful crash course in understanding and using this common drive train controller.

Animations of 75 Different Knots

Via the Tools for Possibilities newsletter comes this amazingly useful resource. Knot-tying is a fundamental maker skill. But learning to tie them from a text, or looking at still images, can make them seem unnecessarily confusing and complicated. I don't know about you, but seeing these knot animations immediately makes me want to grab a rope and go to lashing school.

Maker Slang

Slang, jargon, and technical terms for the many realms of making things.

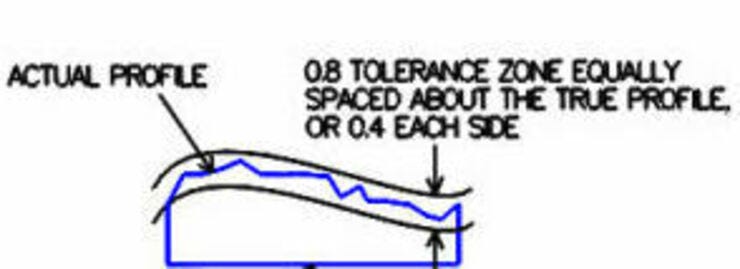

Surface profile -- The 3-dimensional tolerance zone around the surface of an object, often one that's a complex curve or shape. This profile requires that every point along the surface lies within a specified tolerance range.

Slush casting -- A form of casting where material is “slushed around” inside of a mold, creating a thin layer on the outer walls of the casting. This technique is most often used to create a lightweight, hollow castings. It can also be done as the first pour in a highly-detailed mold, with a second pour finishing a solid cast.

The Rule of Cool -- In making anything from realms of the imagination (e.g. sci-fi, fantasy, other fiction), the overriding of realism, the laws of physics, and practicality in the service of sheer cool factor.

Shop Talk

In response to my piece on toilet floats and valve reseating tools, I got an interesting message from a reader. He was taken aback by the fact that doing this sort of basic household plumbing was even a question for me. He assumed that any maker/handyperson would do this type of maintenance/repair work without even thinking about it. This led him to ask: "Is there anything you look at and think: 'I cannot fix THAT!' I’ve never once thought that. Am I in the majority or minority?"

My situation might be somewhat unique in this regard. I have severe spinal arthritis. So, many maintenance, repair, and DIY projects are outside my reach. Even to replace the float tank, I couldn't reach down and shut off the very frozen water intake valve on the toilet. I had to get a friend to come over and do that for me.

But even for the more physically able, I'm sure there are preferences. I know plenty of people who loathe house painting, and others who would never think about doing electrical work. And I know plenty of electronics nerds who build robots, microcontroller projects, and all sorts of other high-tech makery who wouldn't think about doing traditional shopcraft (woodworking, metalwork, etc). And vice versa.

Different strokes for different folks. And so on and so on and scooby dooby dooby.