Gareth's Tips, Tools, and Shop Tales - Issue #88

Skill Set: Silicone Mold and Casting Resin

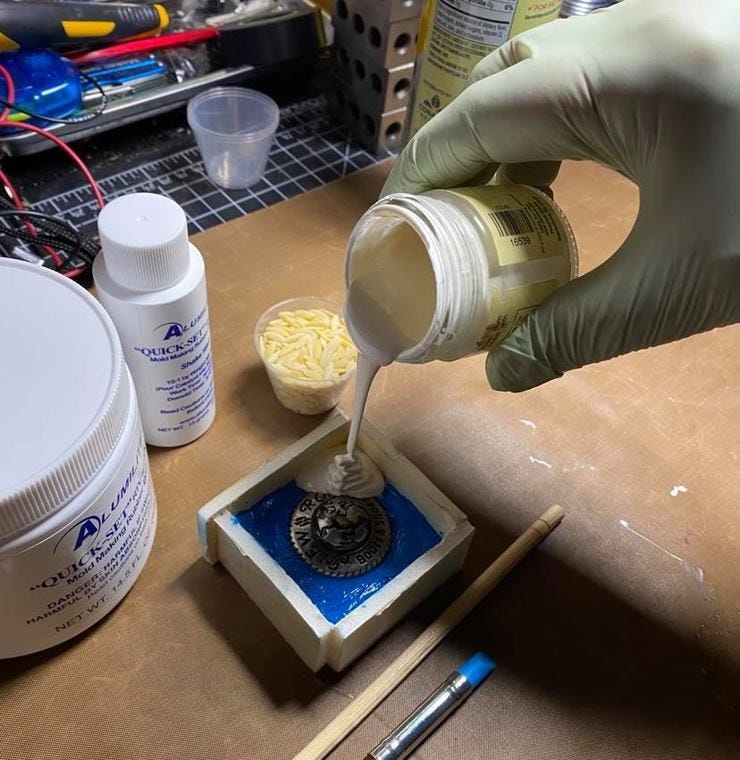

I hope folks who've been participating in this series have been having fun learning a new skill. In the last three segments (1, 2, 3), we've learned the basics of molding and casting a 1-part mold. Above is my pour of my 1-part mold. Reader Federico Tobon of WolfCat Workshop posted his molding and resin casting in an Instagram video. He made a cool CNC-cut character face and cast that (see below). He had some trouble demolding because of the blind holes in his design. He forgot to use a demolding agent (cooking spray is common). The cast turned out great, but he lost some of the mold in removing the piece. Great job, Federico!

If you poured a mold and cast an object, please send me a pic and I'll share it here.

In the next sequence, we'll be building a block mold. This is a type of single-pour mold that allows for more complex shapes and undercuts. As always, refer to Paige Russell's Instructables class for details. Go ahead and choose your object and build your mold box. Make sure to choose a small object so that you don't have to use a lot of the casting rubber. And, as always, ask any questions you may have.

Which Tape Measure is Best?

I've been waiting for this Project Farm video for some time. In it, Todd tests Milwaukee, DeWalt, Stanley, Craftsman, Klein, Kobalt, Lufkin, Bauer, Komelon, Kutir, and Ming Hao 25' tape measures. The tapes were tested for standout (reach), abrasion resistance, impact, retraction speed after exposure to saw dust and sand, magnet strength, and blade lock strength. So, which brands performed best? The $30 DeWalt DWHT36225S followed by the $13 Craftsman CMHT37225S. Given the results, and for $13, the Craftsman will be the next tape I buy. I do have a 25' Craftsman tape measure already, but it's probably 25 years old and doesn't have the more modern features like tape coating, extra standout, and a magnetic hook.

8 Resources for Free (or Cheap) Stuff

In this Jeremy Fielding video, he runs through his favorite resources for acquiring free equipment, parts, supplies, and services. I love his idea of cultivating "agents," family, friends, and colleagues, who know you're on the lookout for cast-off equipment and parts. As he points out, after you have a couple of these agents on the look-out, you'll soon have more free stuff than you can deal with. If you watch Jeremy's channel, you know that he's built many of the machines in his shop from scratch. Lots of the parts for those tools came from old treadmills, washing machines, printers, and the like.

Shop Gloves

Do you have a brand of shop gloves that you prefer? If so, why? I usually just buy the cheapest ones on Amazon. But they tear so easily. I just bought a box of these heavy duty 3 mil nitrile gloves in oh so stylish black. They're non-latex, powder-free, and food safe. They're not super cheap, but I'm hoping the difference is worth it.

More Storage Tech

Alex H sent in these storage tech tips and generously shares his CAD file for the rack he designed:

The above photo is the custom flat-pack storage rack I designed to hold standard shoebox-sized plastic containers. I'd previously kept them stacked 4-high, but getting at the bottom one was always a chore, and heavy bins on the top threatened to crush the ones on the bottom. Now, each has its own slot and is easy to access. The dimensions of the shoebox containers differs slightly by manufacturer, so if you make something like this, verify the dimensions of the style you're using, and buy enough to fill the rack in one go.

I designed the rack to be cut out of 1/4 in plywood on a CNC or laser machine, here (free registration required).

My second tip goes with the link above. My favorite 3D CAD software is a package called Onshape. It's industrial-strength CAD that runs completely in a browser, meaning no install, updates, or machine requirements, and it runs seamlessly across my PC, Mac, and Linux boxes. The company offers a free maker/hobbyist license, only restricted by all created documents being public.

Maker's Muse

I've always had a huge attraction to what Laura Kampf has dubbed "guerilla making." That's where you find something in the public space that's broken and fix it. In this video, Laura finds a broken 3-seat bench along the Rhine river and decides to replace the two missing seats on it. She uses recycled pallet wood. I love the idea of people going around and quietly repairing and improving the commons around them.

Shop Talk

Reader Bob T sent in this tip in response to the item about scoring and snapping small-diameter tubing with a razor knife and a vise:

Just a quick comment on the "razor blade for tubing" tip. Depending on the wall thickness and malleability of the tubing, it's sometimes tricky to get the scoring just right and the tubing doesn't snap cleanly. In that case, insert the butt end of a drill bit that just fits into the tubing to the appropriate depth, and snap off with that as support.

***

Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. Check out the Cool Tools website, the Cool Tools podcast, YouTube channel, and their other two newsletters, What’s in my bag? and Recomendo.