Gareth's Tips, Tools, and Shop Tales - Issue #40

Working with Metal-Infused Filaments

From my piece in issue 29 of HackSpace: Washington, DC-area artist and curator Dave Mordini shared this discovery with me. “I took an old broken lawn ornament and put new feet on it. I then 3D-scanned it using an inexpensive consumer scanner. I decided to add pizzazz to an aluminum casting of it by using copper-infused filament when 3D printing my mold. The 3D-printed mold is packed in sand. When you pour the hot aluminum into the mold, the plastic part gets burned away, but the copper remains.”

Magnets in the Shop

For my next HackSpace column, I am doing a round-up of cool things you can do with magnets in your shop (and in your projects). If you have any good ideas, please share. Here is one of the magnet-related tips from my book, Tips and Tales fr0m the Workshop.

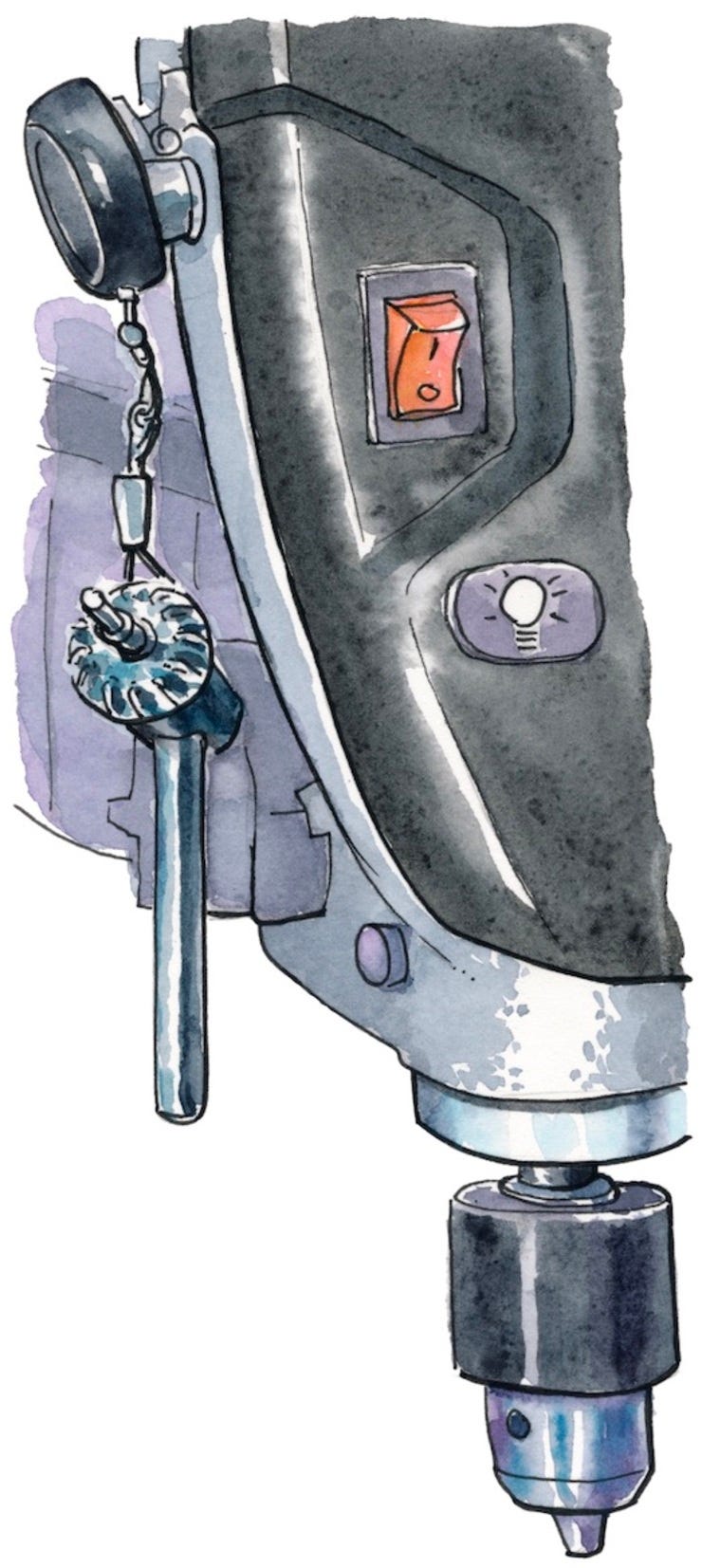

Save Your Drill Press Chuck on a Key Ring: Tired of losing the chuck on your drill press? Use a retractable magnetic key ring to store it close at hand by mounting it on the press itself. [Sean Michael Ragan]

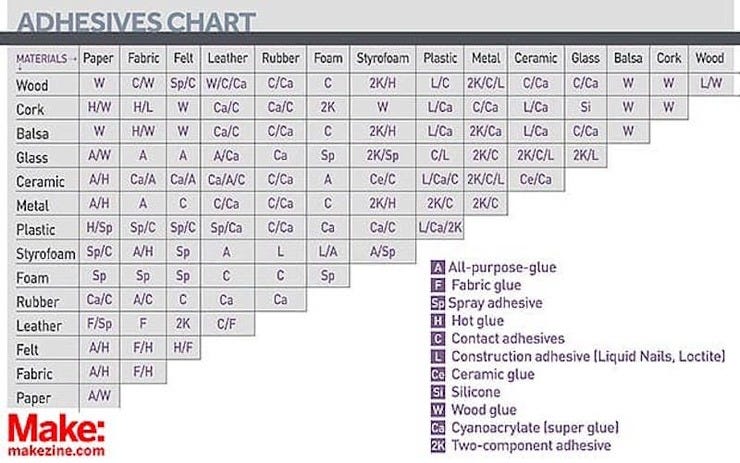

Make:'s Adhesive Chart

Someone posted the above chart to the "Shop Hacks" group on Facebook which reminded me to share it here. We included one of these charts in the Maker's Notebook that I edited and on the Make: website. Here is a larger version.

The Maker's Muse

Via Sean Ragan's Instagram: "A chuck from an obsolete DeWalt cordless drill fit with standoff and a spigot handle for manual drilling, reaming, chamfering, deburring, etc."

Using a Sewing Machine Needle as a Drill?

Here's a tip from the always reliable Emory Kimbrough: "Need to drill a very small diameter hole, but don’t have the needed tiny drill bit? Or, perhaps you do have the bit, but it’s too small for your big drill chuck to get a good grip on? In a pinch, you can try a sewing-machine needle. Unlike needles for hand sewing, sewing-machine needles have an enlarged, sometimes flattened shank that the chuck can grab. Here’s a second useful trick for using a small-diameter drill bit in a large chuck that won’t quite close tightly onto the bit: Find some insulated wire with a gauge equal to, or at least fairly close to, the diameter of bit. Strip off a short segment of the insulation – now you have a little rubbery tube to slide around the base of your tiny bit, providing a larger-diameter gripping surface for the big drill chuck to squeeze."

Shop Talk

I've been getting some wonderful messages and photos in response to my "homely tools" request in the last issue. Show me (and tell me about) your homely tools.

***

Larry Albertelli writes: I have small plastic bottles with different tips, including needle tips, and small vials, with tiny funnels that fit them all. In them I put homemade lubes, solvents, diluted E6000, diluted Lexel. I have plastic and glass syringes with sharp and blunt tips to dispense minute quantities of various lubes and glues. Microbrushes, small makeup brushes, scalpels of various sizes, a carbide tool sharpener which sharpens any blade, from #11 scalpel blade to scissors blades, razor blades, utility blades, you name it, in seconds. The list goes on and on. These are the backbone of a tinkerer/hobbyist/maker.

Reader John Young also wrote to remind us all of the oldie but goodie of tacking up an old hacksaw blade on the edge of a workbench or elsewhere to use for cutting sandpaper to size. You can also use such an arrangement to cut kraft paper and other similar materials.

***

Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. Check out the Cool Tools website, the Cool Tools podcast, YouTube channel, and their other two newsletters, What’s in my bag? and Recomendo.