Gareth's Tips, Tools, and Shop Tales - Issue #31

Etching Metal with a 9v Battery

Leah of See Jane Drill demonstrates how easy it is to etch a metal surface using little more than a 9v battery and wires, vinegar, salt, and Q-tips.

Screwing in Bolts with a Pencil Eraser?

In this little video Izzy Swan shared on Facebook, he demonstrates how you can chuck a pencil into a drill and use its eraser to drive home a flat-headed bolt or other fastener. Great for those hard to reach places. [H/t Caleb Kraft]

Casting with Cardboard and 3D Molds

On XYZAidan, young maker Aidan shows how he created a series of molds on his 3D printer and cast cardboard pulp in them that he made in a blender from cut bits of cardboard trash. With this technique you could shape all sorts of 3D objects from paper.

Finding the Thickness of a Wire

Emory Kimbrough was one of the winners of my Tips book drawing last month. I asked contestants for one great tip. Emory sent me ten. And then, a few days later, he sent me five more -- all publication-worthy. I'm excited to share them. Look for many Emory tips in the coming months. Here's the first one:

If you need to find the thickness of a wire but don’t have a micrometer or calipers, wrap the wire around a dowel many times in a tight helix leaving no gaps between the coils. Now, just measure the width of, say, thirty coils with an ordinary ruler and divide by thirty. The more coils you wind, the more accurate your measurement. And even if you do use top-quality digital calipers, it’s even more accurate if you use this wind-and-divide method than if you measure a single thickness.

Tips for Drilling Metal

More words of wisdom from Emory Kimbrough:

1) If you need to drill a lot of holes through metal, fill a soda bottle cap (or similar tiny little cup) with whatever cutting fluid you’re using as a lubricant and coolant. Position this just below the hole in your drill press table and adjust the press so that the tip of the drill bit will dip into the cup at the bottom of its travel. Now, every time you drill a hole, you’ll automatically be re-lubricating your bit.

2) If you don’t have one of the many commercial coolant/lubricant products on hand that are sold as cutting fluids or tapping fluids, then using 3-in-1 Oil, WD-40, baby oil, mineral/paraffin oil, or even cooking oil. They are all better than using no cutting fluid at all. Single-weight, non-detergent motor oil also works well, however, do not use multi-weight motor oils or oils with detergents and additives. Those can corrode copper, brass, and bronze – and even if you’re not drilling into those metals, that expensive power tool you’re using could have copper parts and wires inside.

3) You’ve been lied to! A ¼” round drill bit will not drill a ¼” round hole. The tip of the bit will wobble around a little, even if secured properly in a good drill press. Thus, the hole will be slightly larger than the size of the bit, and it won’t be exactly round. For woodworking, this tiny error is almost always too small to matter, but in metalworking, it can be important. For example, you may need a shaft to turn or slide very smoothly but without any play or vibration in a hole drilled in metal. For this, you need a reamer. This tool looks somewhat like a tap, with cutting edges on the side instead of the tip. To use it, first drill a hole just slightly smaller than the desired diameter, then follow that with the reamer, taking out just a wee bit more material to create a perfectly round hole of the exact desired diameter. Yes, you’ll want a drill press or a lathe for this, not a hand-held drill. An added benefit: the reamer will create a much smoother bore than a drill bit.

Sean Ragan Looks at Wave-Opening Pocket Knives

Have you ever heard of a "wave-opening" pocket knife? I hadn't until watching this Cool Tools video. It's a knife design that includes a little hook which catches on your pants as you remove it, making you quick on the draw as the blade is deployed in a single, fluid motion. Sean looks at two such knives and likes what he sees in this Kershaw-Emerson model.

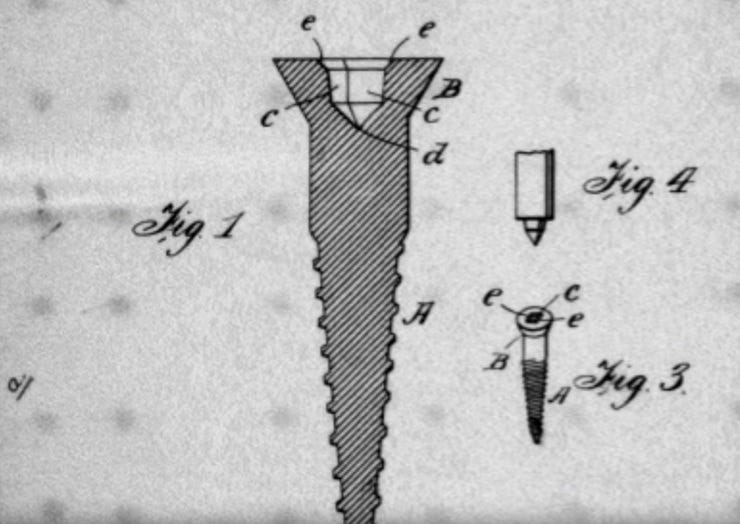

Must-See Maker TV: History of the Screw

I love The History Guy on YouTube. In this episode, he examines the history of the screwdriver and how world events shaped the development of the Phillips head and Robertson head drivers and screws. Even if you know something about the history of this ancient technology, you will likely learn some cool things from this video.